We design novel processes for smart manufacturing combining 3D printing and foaming to produce innovative green materials.

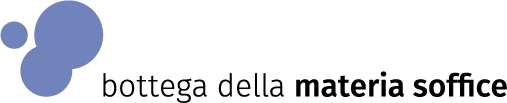

Foaming processes are extensively operated in polymeric cellular materials industry to produce pores, yet without spatial control of their positioning. This intrinsic stochasticity may introduce imperfections, which reduce the mechanical properties of the material, thus regular (e.g., periodic) porous structures would be more desirable. 3D printing allows to fabricate polymeric cellular materials with empty spaces in a well-defined periodic structure. To this end, very expensive 3D printers are required to achieve micron-resolution pores. Correspondingly, the production time is dramatically large and becomes a bottleneck to the industrial scale-up. Herein, an innovative technique combining the simplicity of polymer foaming with the precision of 3D printing is designed and studied.

Manager: Daniele Tammaro

Members: Claudio Esposito

Smart manufacturing

We study simple and cost/time-effective 3D printing techniques to produce microfoamed strands in only one step. The results show a fine tuning of cell morphology in the printed strands by designing the operating conditions through the modeling of transport phenomena.

The results show special mechanical properties depending on the cellular morphology and deposition strategy.

The proposed approach opens up a broad scenario of opportunities to optimize mechanical, thermal, and electrical properties of 3D printed structures.

Advanced packings for separation technology

Packed columns are largely adopted for multi-phase reactors and separators, i.e., distillation, production or purification of commercial products, flue-gas treatment, conditioning and requalification of air for indoor systems, and cooling of industrial waters.

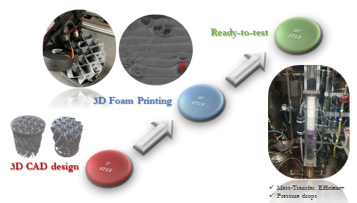

Fig. 3: from the idea to realization of packed columns by smart manufacturing.

For testing our innovative 3D printing with foam we designed, manufactured and characterized an innovative 3D foam-printed packing suitable for process intensification in multi-phase reactors/separators, which in the specific case was applied to scrubbers for flue-gas desulfurization. The packing prototype has the advantages to be light, easy-to-produce with a customized design also with green and biodegradable raw materials.

The experimental results indicated that the new packing had higher mass transfer efficiencies when compared to some of the commercial packings of similar design.