Our group studies fundamentals and modelling of interfaces by experiments and numerical simulations.

Interfaces between two fluids are ubiquitous in nature and industrial processes. Understanding of interfaces dynamics is crucial to tuning the stability thin films in a number of important applications such as for stabilizing foams in foods and beverages, destabilizing foams in lubricants, avoiding surface irregularities in liquid coatings and treating ophthalmic disorders originating from the unnatural breakup of the tear film.

Fluid/ fluid and fluid/air interfaces are often characterized by rheological complexity and the relationship between surface velocity gradients and surface stresses can be highly nonlinear. Understanding this relationship requires the knowledge of many aspects of interfacial science, starting with the thermodynamics of these systems, since constraining molecules to an interface can lead to a very rich phase behavior.

Our aim is to elucidate the role of interfacial properties on the dynamics of thin films when deformed. The study is carried out by experiments and direct numerical simulations.

Manager: Daniele Tammaro, Massimiliano Maria Villone

Members: Luigi Davide Gala

Collaborations: Marco De Corato (University of Zaragoza)

Equipment

Oscillatory Fluid Interferometer (OFI)

A setup made of a interfermeter with visible light that is able to measure thicknesses between 20-900 nm. Beyond the state-of-art, the setup is able to measure oscillating thin films.

Bubble bursting setup

A setup made of a syringe pump (model 22, Harvard Apparatus), pressure transducer and 3D printed parts is able to inflate bubbles at different speeds and sizes. The rupture dynamics of thin films is usually recorded by using a fast camera (i-speed 3, Olympus) that is able to reach 100000 frame per seconds.

Bubble bursting dynamics: viscoelasticity and “flowering”

The lifetime of bubbles, from formation to rupture, attracts attention because bubbles are often present in natural and industrial processes, and their geometry, drainage, coarsening, and rupture strongly affect those operations. Bubble rupture happens rapidly,and it may generate a cascade of small droplets or bubbles. Once a hole is nucleated within a bubble, it opens up with a variety of shapes and velocities depending on the liquid properties. A range of bubble rupture modes are reported in literature in which the reduction of a surface energy drives the rupture against inertial and viscous forces. The role of surface viscoelasticity of the liquid film in this colorful scenario is, however, still unknown. We found that the presence of elasticity affects the busting time of a bubble and that the interfacial viscoelasticity has a profound effect in the bubble bursting dynamics. Indeed, we observed different bubble bursting mechanisms upon the transition from viscous-controlled to surface viscoelasticity-controlled rupture. When this transition occurs, a bursting bubble resembling the blooming of a flower is observed. A simple modeling argument is proposed, leading to the prediction of the characteristic length scales and the number and shape of the bubble flower petals, thus paving the way for the control of liquid formulations with surface viscoelasticity as a key ingredient. These findings can have important implications in the study of bubble dynamics, with consequences for the numerous processes involving bubble rupture. Bubble flowering can indeed impact phenomena such as the spreading of nutrients in nature or the life of cells in bioreactors.

1. 2021 PNAS, Tammaro et al. “Flowering in bursting bubbles with viscoelastic interfaces”.

2. 2018 Langmuir, Tammaro et al. “Elasticity in bubble rupture”.

The role of surfactant and elasticity in the retraction of thin film

Fig. 3: (A) Sketch of the experimental sequence including bubble inflation, hole formation, and film retraction. (B) Numerical “equivalent” system, with the arrows representing the applied stretching force. (C) Section of the geometry of the experimental system at hole formation.

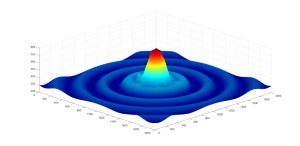

When a Newtonian bubble ruptures, the film retraction dynamics is controlled by the interplay of surface, inertial, and viscous forces. We study the retraction of a circular thin film coated with insoluble surfactants, which is punctured at its centre. Our simulations show that the surface elasticity introduced by the surfactants slows down the retraction and introduces oscillations at early times. In agreement with previous experiments and theoretical analysis, we find that the presence of surfactants introduces perturbations of the film thickness over progressively larger distances as the surface elasticity increases. The retraction speed of the hole undergoes oscillations at early times, which are caused by the elasticity of the surfactant-coated interface.

These oscillations are caused by the fast initial compression of the interface, which generates a local accumulation of surfactant near the hole edge that slows down the retraction. After the slowdown, the speed increases again due to the formation of a steep gradient of concentration of surfactant and large Marangoni stresses that promote the opening of the hole.

Fig. 4: Retraction speed of surfactant-laden thin films as function of elastocapillary number, comparison between simulations and experiments.

The steep gradients of surfactants are then smoothed progressively over longer distances by the Marangoni flow. At longer times, the retraction speed reaches a steady-state value that decreases as the importance of surface elasticity over surface tension increases.